Q: What do I need to utilize CartACE?

A: InCommand displays with a DisplayCast unlock in both the combine and grain cart, AgFiniti Essentials license, matching GPS sources, & internet hotspot

Q: Is there a CartACE license?

A: No, only what is listed above is required

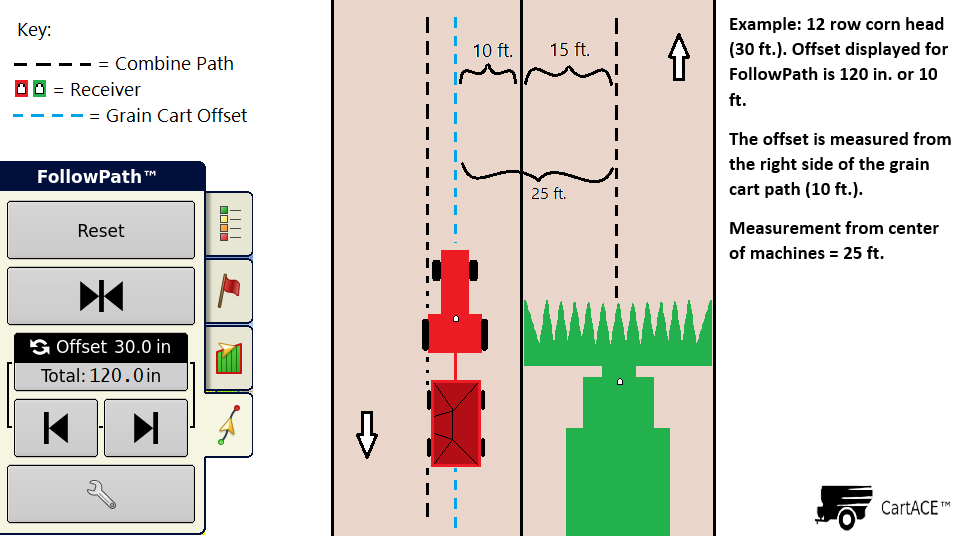

Q: How does the grain cart know what guidance line to follow?

A: Uses previous combine path to generate new line, this feature is called FollowPath. The cart operator can center cart in specific location in order to maintain proper spacing.

Q: What GPS and Correction Source do I need?

A: There is not a correction requirement, although you must be using the same correction in both combine and grain cart.

Q: How does the system know which combine’s coverage to follow?

A: CartACE knows which combine it is closest based on DisplayCast position.

Q: Can you use other data besides Harvest to create FollowPath guidance?

A: At this time, only Harvest events can be loaded for use with FollowPath. Note, reference layers can still be loaded in the background.

Q: Will FollowPath work through waterways or other similar path disruptions?

A: Yes, as long as the break is less than 100ft and the pass on the other side was logged continuously. For example, if the combine picked up the head, drove thorough small waterway then set head back down, the line would be continuous.

Q: Is an auto steer system required to use CartACE?

A: No, a steering system is not required to use CartACE. But in order to get the benefit of FollowPath, Ag Leader recommends using either SteerCommand Z2 or SteadySteer to follow the generated path.

Q: When does the Live Grain Tank Reset Sensor re-calibrate?

A: After every event change or power cycle.

Q: How much data usage will using CartACE add to my system usage?

A: Should not add any data usage on top of what is already used when operating DisplayCast. Keep in mind that as additional displays are connected and syncing, more data will be used.

Q: What does the Live Grain Tank Counter Reset do?

A: It automatically resets one of the bushel counters in the combine when unloaded. This information is shared over DisplayCast providing valuable information to the operation and can be used to directly grain carts where they are needed most.

Q: How does the Live Grain Tank Counter work?

A: A sensor is installed in the grain tank on your combine and connected to a module. When the sensor is uncovered, the counter is reset. When the sensor is covered, the bushel counter gets set to a calibrated value and counts up with the flow sensor.

Q: Who can see the Live Grain Tank Counter data?

A: Any grain cart configuration will see specific counters for all connected combines on the run screen. This information can also be accessed in AgFiniti Mobile.

Q: Can CartACE be used with multiple combines in the same field at the same time?

A: Yes, CartACE/FollowPath works with multiple combines at the same time as long as they are participating in the DisplayCast event.

Q: Can CartACE work with multiple combine header widths?

A: Yes, the grain cart operator will need to create an offset by centering under the auger for each combine in the DisplayCast event. Once they have an offset for each combine, the display will automatically switch between the combine specific offsets based on position.

Q: What do I need to do to use the Live Grain Tank Reset Sensor?

A: Purchase kit 4006109 which includes the sensor, module and associated cabling all to be installed on the combine.

Q: Does the Live Grain Tank Reset Sensor show level?

A: The sensor does not show level, it automatically resets of one of the bushel counters on the mapping screen.

Q: Will the Live Grain Tank Counter work in CLAAS configurations?

A: Yes, a CAN extension will be needed to get a CAN A to the grain tank and module. Refer to install instructions for additional details.

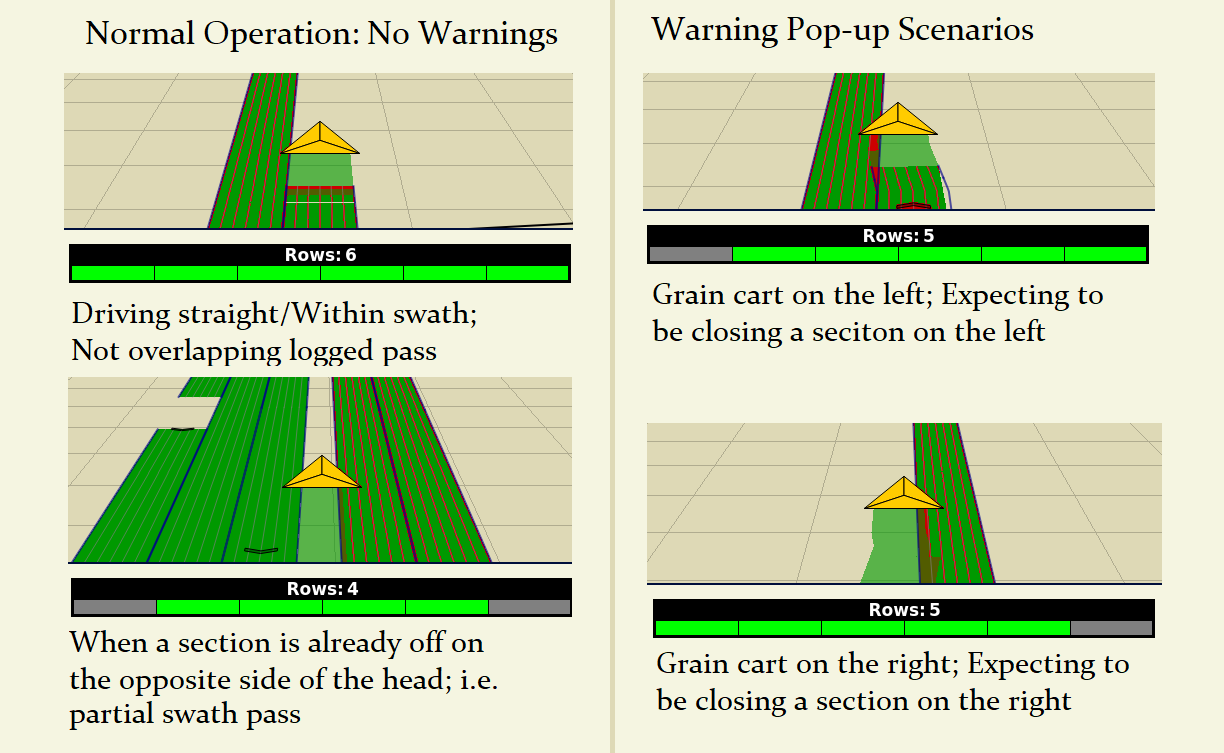

Q: How does the CartACE collision warning work?

A:The combine will use the width of the head as well as a defined look ahead distance in conjunction with its previously logged data to determine a collision zone. If a grain cart is in the vicinity, then an onscreen warning will occur in the combine indicating a potential collision.

Q: Does CartACE/FollowPath prevent the collision?

A: No, it will still be up to the combine and grain cart operator to avoid any potential collision.

Q: How is the offset from the combine calculated?

A:

Q: When will a collision warning trigger?

A:

Other Helpful Knowledge Articles: